SERVICES

-

In-Water Survey

The Company is approved by all leading classification societies and has performed thousands of statutory surveys worldwide.

Full underwater video inspection and survey services are provided to meet Classification Society requirements and standards. The latest underwater digital video equipment is used to providing direct-live information to surveyors and shipping company representatives, of which help reducing the need for drydocks.

Full written report and DVD will be provided to demonstrate the quality of work performed. Recognized Classification Societies » View

-

Inspection

Repair starts with an inspection. Our engineers have the capability to record real time data with instant playback. Inspection using CCTV is also available. Underwater inspection includes complete hull survey, pre-purchase survey, dry-docking extension survey, paint coating survey, grounding survey, fouling condition, damage inspection, ultrasonic plate thickness measurements and corrosion protection analysis or any other purposes. These are carried out with modern inspection techniques by certified inspection divers.

-

Maintenance | Propeller Polishing

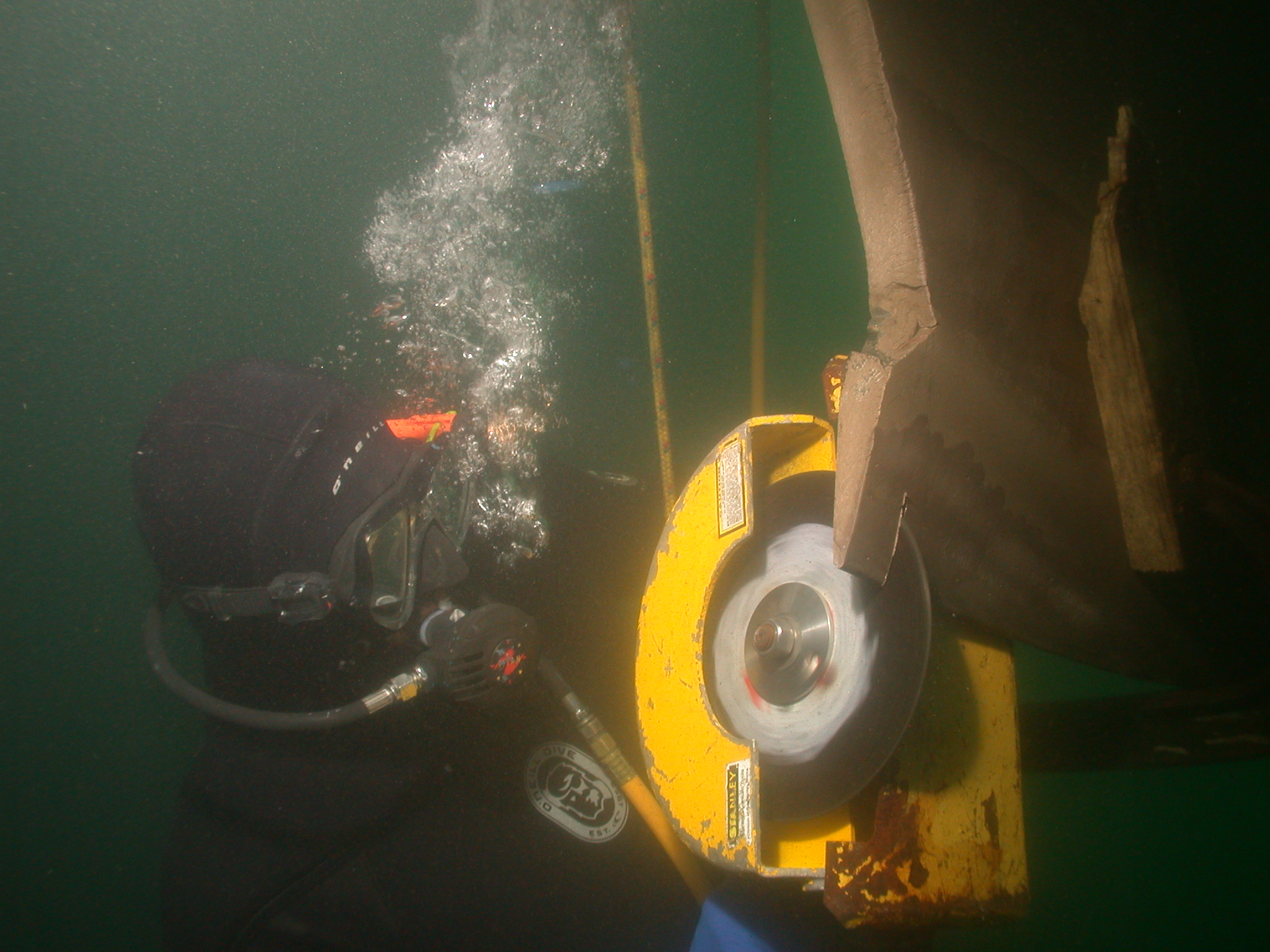

Polishing of the entire propeller and removal of marine growth, calcium and basal plate deposits without gouging of the surface is achieved using the Scotch-Brite marine cleaning disc.

When the propeller roughness increases, it decreases the efficiency of the propeller and let the colonization of the unit by marine fouling, eventually increasing drag and fuel consumption. The surface finish of the blade is much critical than most ship owners realize, at the same time a few micron of increased roughness will increase fuel consumption.

Water is a natural lubrication for propeller polishing, therefore in -water polishing gets a finish far superior to that of dry polish. The Company performs propeller polishing based on accepted standards and guarantees excellent surface finish, 1 micron Center Line Average (C.L.A.).

Finishing of the entire propeller and removal marine growth, calcium and basal plate deposits without gouging of the surface is achieved utilizing the special equipment. Routine propeller polishing can save fuel and money.

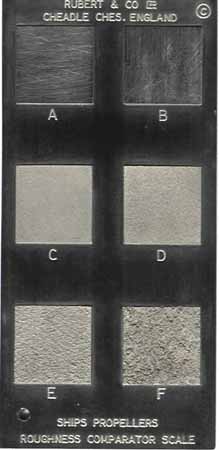

Ships propellers roughness comparator scale provides the guideline of the limits for the propeller roughness.Underwater Hull Cleaning » View

-

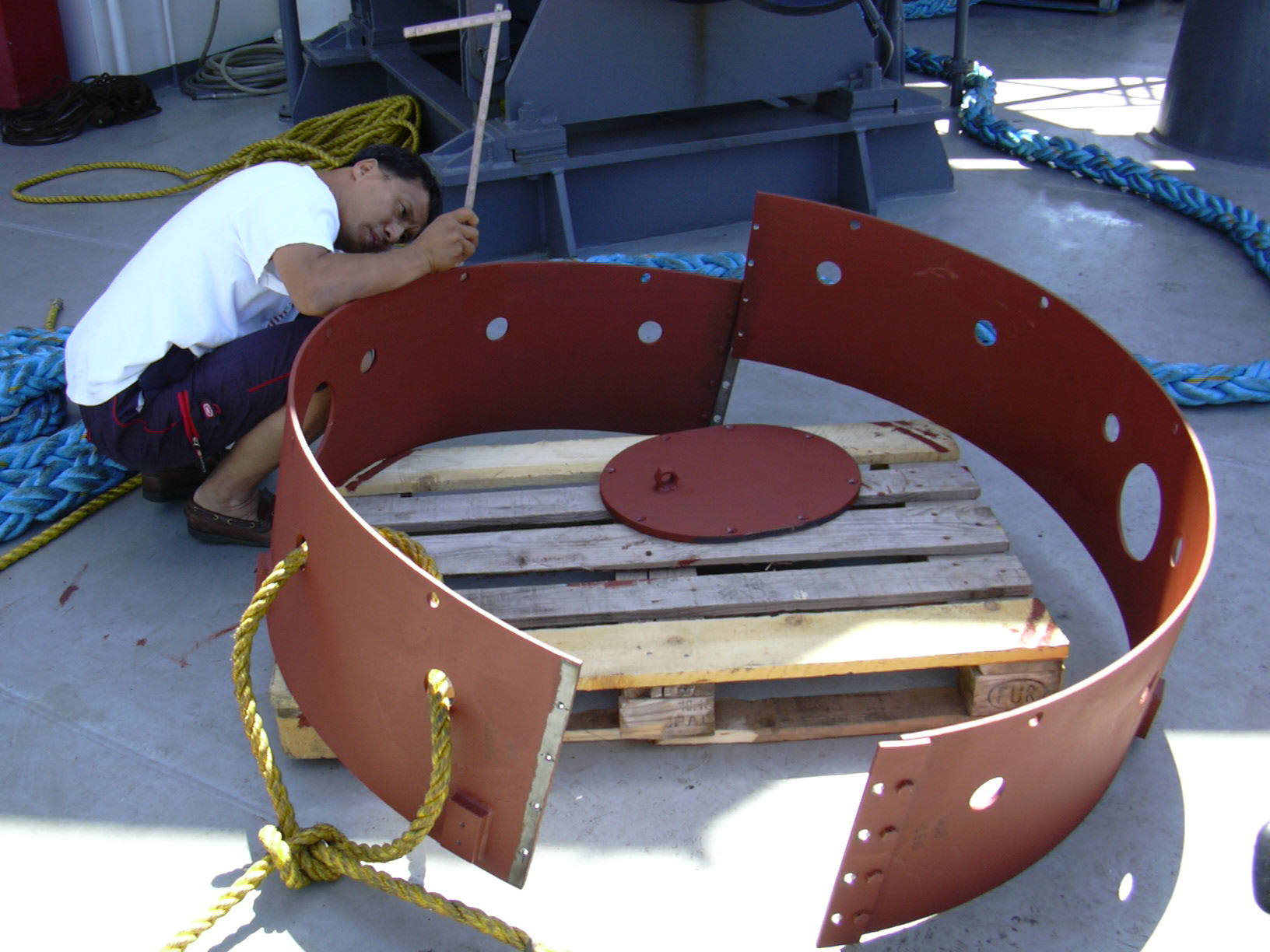

Underwater Repairs

All types of underwater repair and maintenance can be undertaken including anode replacement, crack repair, propeller re-balance, hull aperture blanks, cutting and welding. The Company has extensive expertise in temporary and permanent repairs where major change has occurred.

All types of underwater repair and maintenance can be undertaken including anode replacement, crack repair, propeller re-balance, hull aperture blanks, cutting and welding. The Company has extensive expertise in temporary and permanent repairs where major change has occurred.

We can provide the additional expertise and resources needed to handle the more complex repair work.

We are available 24 hours a day, 7 days a week, including weekends and holiday.

-

In-Water Survey | Recognized Classification Societies

American Bureau of Shipping

Bureau Veritas

Germanischer Lloyd

Korean Register of Shipping

Lloyd's Register

Nippon Kaiji Kyokai

RINA

China Classification Society

-

Maintenance | Underwater Hull Cleaning

The marine growth can affect a ship hull in many ways such as :- Increased deadweight, waveloading and drag

- Exaggeration of corrosion

- Concealment of metal surface features and defects from inspection

- Reducing or blocking of seawater intakes

A ship's fuel performance usually begins falling off around eight months after drydock and continues to deteriorate rapidly. Underwater marine growth can cost a ship owner millions of extra dollars in time and fuel each year.

To maximize fuel savings and reduce deterioration of costly hull protective coatings, cleaning can remove accumulated marine growth from ships bottoms or submerged offshore structures.Propeller Polishing » View